You will constantly be hearing about NEMA16, NEMA23…

NEMA is the acronym for National Electrical Manufacturers Association.

When it says national, it really means USA. It is quite a paradox that every NEMA you buy uses the ‘national’ standard, but they are Made in China.

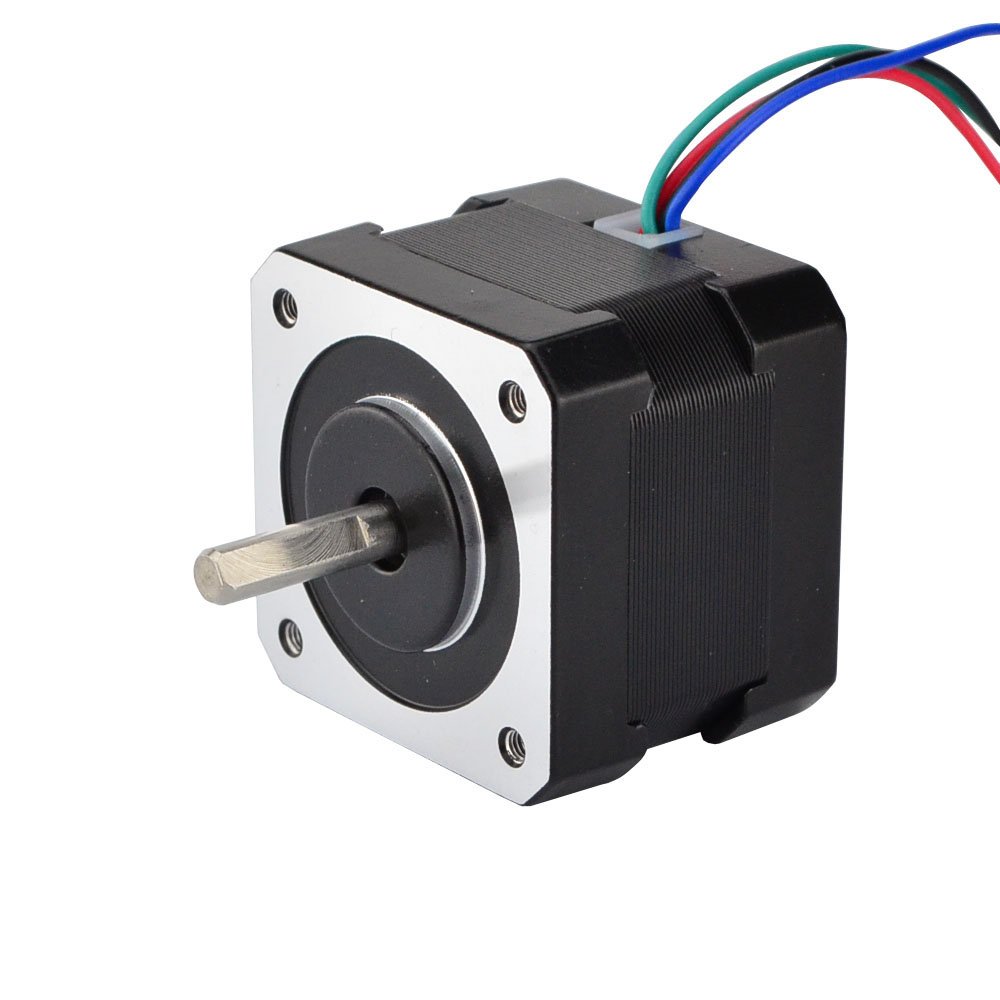

The number will indicate the size of the motor. To be more precise it will specify the front face, where the screws are located. NEMA17 means it’s dimensions will be 1.7×1.7 inches.

It’s implied that usually the bigger the more torque will provide. Although it doesn’t have to be like that. It is totally feasible for a NEMA14 to over-match a NEMA17. It depends on the manufacturer and the specs of the motor design.

If the motor will be in a dynamic part of the machine, like the head or an extruder, then the size will really matter. The bigger the more weight, that will generate more momentum.

The NEMA14 are very light, but they are difficult to obtain with the necessary torque. The NEMA17 are the easiest to find and the most common ones for Arduino projects.

Which motor to buy?

Álvaro Rey, from MakerGal: If you are in doubt about which NEMA17 to choose, always buy the biggest. If you are afraid of not having enough torque get one of big 70oz.

Heat

Bear in mind that motors tend to get into quite a temperature. If they work at top of their specs, it is not uncommon for them to get to 80º degree Celsius. And if you happen to use PLA plastic for your machine…

You might end in big trouble!

Resistance

One of the motor characteristics is the internal resistance. How this influence us?

On one side it is the heat released. Due having more resistance, the motor will heat more.

Voltage

This value also generates lots of confusion. It is very common for the motor to have a value like 3.6V, but we obviously have a 12V power supply. What can we do?

Motor Voltage and the power supply

It totally different the maximum motor voltage than the driver voltage.

Shaft Type:

It is important to check the shaft diameter and the length.

Make sure you are going to use the gears correctly and to secure the setscrews firmly.

Also, make sure the gear will fit in the motor and the shaft to not be too long.

I am quite pedantic over it since it is not the first time I suffered that problem, or that i have to short the length of a shaft.

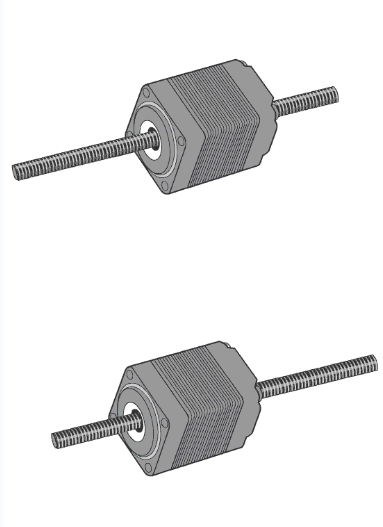

Shaft types

There are 3 types

Round shaft. The most common one.

Flatted section shaft. It is round but it has a flat section. Therefore we can use them with a setscrew easily.

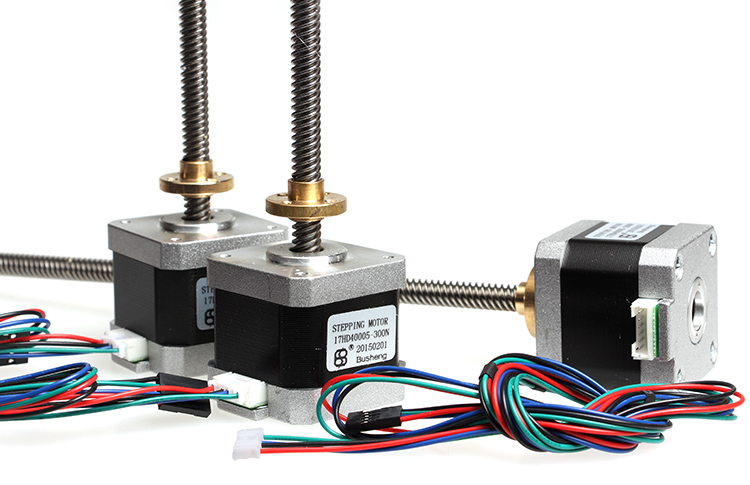

Threaded shaft. Since it is also very common to attach a threaded shaft to the motor, there are motors which already come with a threaded shaft installed to be used with a nut. It is even possible to order them to specs.