What is a CNC Stepper Motor and How Does it Work?

The CNC Stepper Motor is a type of stepper motor that is used in CNC milling machines and CNC lathes. It is a motor that has an armature with multiple coils, which are connected to the X, Y, and Z axes of the machine. It is widely used in many different applications such as manufacturing, engineering, and dental equipment.

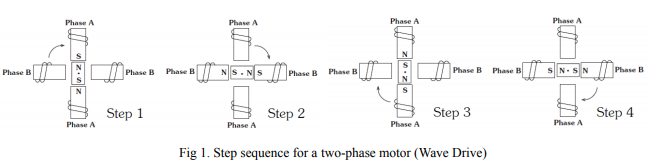

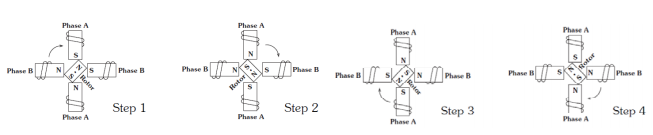

A stepper motor is an electrical machine with an armature consisting of many coil windings. The coils are energized by pulses from a power supply that rotate the armature in increments or steps around a fixed axis (usually the shaft). A stepping motor can also be called a CNC milling machine or CNC lathe. A machine tool is typically used to create parts such as gears, pulleys, bearings, and brackets using various types of cutting tools such as saws, drills, and mills.

CNC Stepper Motor is an electrical machine that converts electrical current into rotation. It has the ability to rotate at very high speeds with precision. The speed of the motor depends on the number of steps it takes to complete one revolution.

They are designed to have a high torque output which makes them suitable for use in turning tools like lathes, mills, and drill presses.

Try to understand the Torque, RPM, NEMA specifications of stepper motors can be overwhelming when building your CNC. It is easy to make mistakes when choosing the right one and end up with an overkill setup or a weaker system. This article is intended for DIY enthusiasts and hobbyists to help them choose the best stepper motor to meet their project and CNC router needs.

In the following, we will show you how to quickly choose the right stepper motor for your project. I will also talk about the many factors to consider when choosing a stepper motor.

These are important considerations when choosing a similar CNC machine.

Your gantries should be roughly equal in weight to your gantries

Each axis should have the exact same linear drive components

It is important that the size of the machine be identical (the same footprint and work area).

The spindle weight must be the same

You could use the stepper motors if you find a CNC machine similar to what you are looking for.

You could also review the product to determine if it meets your needs. If you have any question on choosing CNC stepper motor, please feel free to contact us at oyostepper.com.

Source:https://gotartwork.com/Blog/how-to-choose-a-cnc-stepper-motor-with-useful-standard/50880/