Step Modes

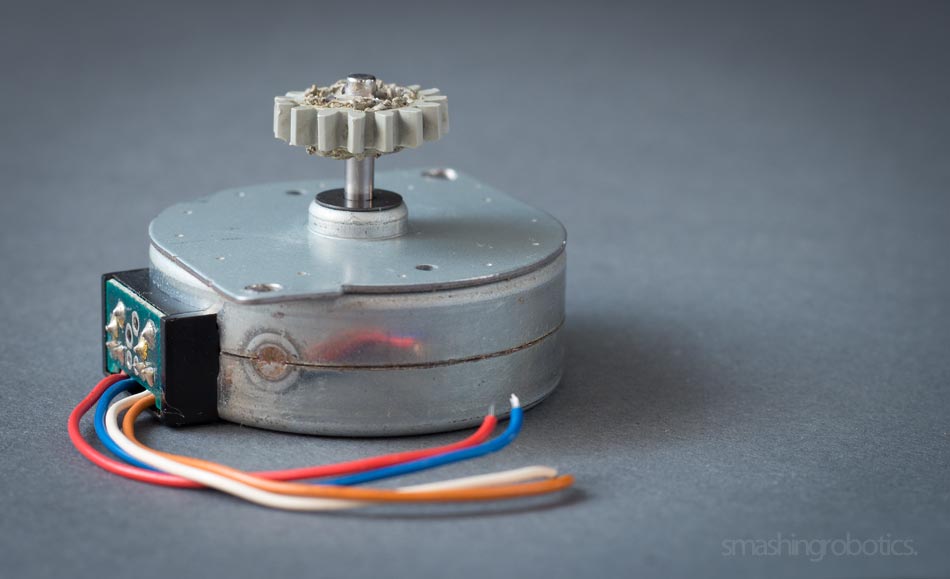

Stepper drivers for sale online come in a variety of step modes, which influence the rotation speed, size, and action of the drive shaft. A complete set of steps does not necessarily imply a full rotation of the drive shaft. In some instances, multiple complete step sequences are required to achieve a quarter of a turn of the drive shaft. The following sections discuss several different step modes and their characteristics.

Wave Step Mode

Wave step mode is found on a number of older stepper driver models. Wave step mode involves passing energy to one phase of the motor at a time. This creates fluctuating torque, which is unstable. It is also considerably less efficient than other step modes, because energy is lost in between energizing each phase. Because of the energy loss, less torque is produced than with other step modes.

Full Step Mode

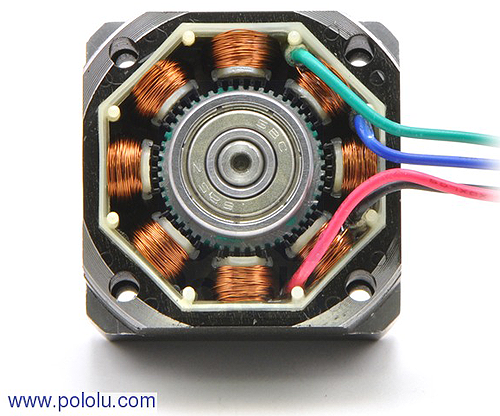

With a full step mode driver, both phases of the motor are energized simultaneously and continuously. This produces full torque for all phases of the motor at all times. Full step motors are very stable, and one complete turn of the drive shaft is equal to one complete step sequence. For example, if there are 50 steps in the step sequence, 50 steps equals one 360-degree rotation of the drive shaft.

Half Step Mode

Half step mode is an alternating energy circuit. First, one coil phase is energized, swiftly followed by both coil phases being energized. This technique doubles the resolution of the step sequence. It creates varying degrees of torque because the single coil phase energy produces half the torque of the double coil phase energy. High end models decrease the torque differential by increasing the amount of current that passes through the single coil phase. This enables the single coil to increase torque output. Half step mode is very stable and doubles the possible resolution and number of step positions. A 50-step sequence step motor capable of operating in half step mode to allow for greater resolution has 100 step positions.

Micro Step Mode

Micro stepping mode is only available on high end cheap stepper motor drive models, and, as such, are more expensive than other kinds. Micro stepping energizes each coil to a set fraction, allowing fractional steps to occur. This creates very high resolution and precise stepping. Micro stepping creates a very smooth step motion, and some models can move at 1/256th of a step.