The stepper motor (and power supply voltage) that you choose should depend on what you intend to do with it. Ideally, the stepper motor must provide sufficient power at the highest speed based exactly on what the application requires. Hence, you need to make sure that it does not exceed specific speed requirements. For instance, a maximum shaft power that you can sustain with a drive that functions at 80VDC and 7A is one third of a horsepower or at 250W. In this case, you need a triple or double stacked NEMA 34 motors.

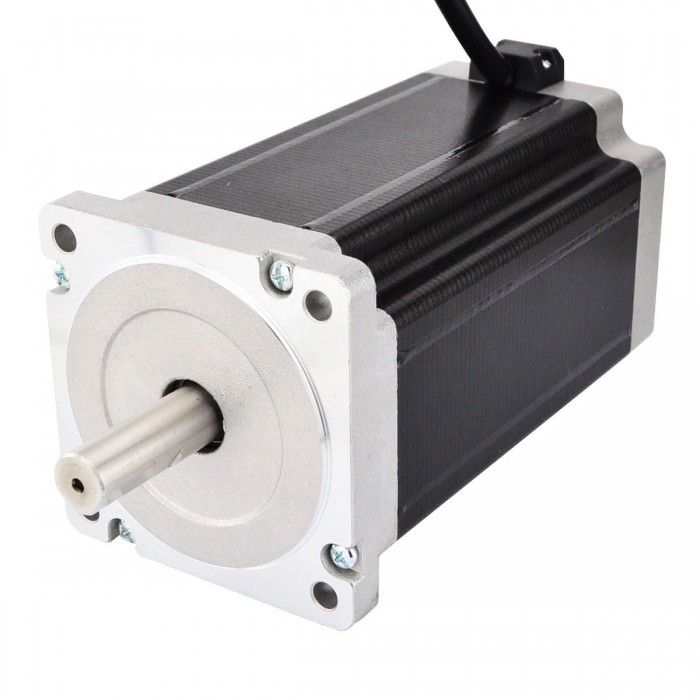

‘NEMA 34’ pertains to a frame size that is 3.4 inches in diameter. NEMA 34 stepper motors for sale have different lengths to suit various applications, like CNC mills and industrial machinery. NEMA 34 motors are ideal for mechanical power of about 200 watts. Reliability is a factor that can determine the type of power that you need for motors. Step motors are typically open-loop, so if you want a design that can generate full torque, the NEMA-34 is a good choice.

You have two choices when you need to use NEMA 34 stepper motors in a bipolar mode, which is advisable to ensure the best performance. Your first choice is to go for a parallel type for a high-speed motors, and the other is to go for the series type connection if you need to limit the phase current. Some suppliers of motor parts can customize the size of the shaft. For example, a 14mm shaft provides stability when used with a belt transmission.

The high torque of NEMA 34 motors makes them suitable for special CNC applications. They can be customized to suit certain requirements. Leading suppliers of small motor parts can customize the housing and winding to make sure that you are getting NEMA 34 stepper motors that are according to your specific application needs and dimensional requirements.

NEMA 34 stepper motors (nema 23 geared stepper motor)can be customized to suit special lengths or have Teflon leads, heat shrink, connectors, pins, and cable harnesses. Some suppliers can provide lubricant and bearing options in case you need NEMA 34 stepper motors for humid or high-temperature environments. Look for a reputable supplier of small electric motors that has a global presence to minimize your supply chain costs.