1.Basic learning of linear stepper motor

A linear stepper motor converts electrical pulses into linear motion by using a threaded screw and a nut, where the motor’s rotational movement is converted into a straight, precise movement. The motor’s rotor turns, causing either the screw or the nut to move linearly along the other, depending on which part is fixed. Key features include precise positioning, high repeatability, and a smooth, controlled movement, making it ideal for applications like robotics and automated machinery.

2.Working principles of linear stepper motor

1.Coil Energization:When current flows through a coil, it generates a magnetic field. Depending on the polarity of the current, one side of the coil becomes a north pole and the other a south pole.

2.Magnetic Alignment:The magnetic field produced by the coil interacts with the magnetic poles on the platen. The forcer aligns itself with the nearest corresponding poles on the platen to minimize magnetic reluctance (the resistance to magnetic field flow).

3.Sequential Switching:By energizing the coils in a specific sequence, the forcer moves incrementally from one position to the next. Each step corresponds to one input pulse, allowing highly controlled, digital-based motion.

4.Direction and Speed Control:Direction of movement depends on the order of phase excitation. Reversing the sequence reverses the motion.Speed depends on the pulse frequency; higher pulse rates result in faster movement.

3.Main types of linear stepper motor

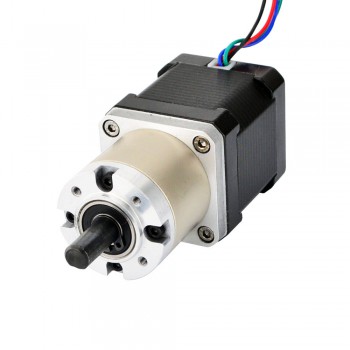

1.Ball Screw Driven Linear Stepper Motors:Ball screw driven linear stepper motors combine the advantages of precision ball screws and stepper motors. They utilize a ball screw mechanism to convert the rotary motion of the motor into linear motion. This type of linear stepper motor provides excellent precision, high thrust capability, and efficient operation. It finds applications in CNC machines, robotics, and industrial automation.

2.Lead Screw Driven Linear Stepper Motors:Lead screw driven linear stepper motors are similar to ball screw driven motors but use a lead screw instead. This makes them more cost-effective, suitable for applications that do not require extremely high precision. They are widely used in applications such as 3D printers, scanners, and medical equipment.

3.Linear Induction Motors (LIMs):Linear induction motors (LIMs) operate on the principles of electromagnetic induction. They consist of a primary winding, known as the primary reactance, and a secondary winding, known as the secondary reactance. When an alternating current is passed through the primary winding, a magnetic field is created, inducing current and a resultant magnetic field in the secondary winding. This interaction generates a force, propelling the secondary part in a linear direction. LIMs are utilized in transportation systems, levitation devices, and materials handling.

4.Linear Switched Reluctance Motors (LSRMs):Linear switched reluctance motors (LSRMs) are based on the concept of reluctance. They consist of a moving part, known as the translator, and one or more stator windings. By sequentially energizing the stator windings, a magnetic field is created that attracts the translator to a specific position. LSRMs are known for their simplicity, efficiency, and reliability. They are suitable for applications such as pumps, conveyors, and robotics.

5.Linear Hybrid Stepper Motors:Linear hybrid stepper motors combine the principles of permanent magnet stepper motors and variable reluctance stepper motors. They utilize a hybrid rotor design, with both permanent magnet and magnetic pole teeth. This hybrid design provides high torque, precise positioning, and improved stepping resolution. They are commonly used in medical equipment, semiconductor manufacturing, and positioning systems.

4.Protection methods of linear stepper motor

1.Adequate Enclosure and Protection:Linear stepper motors should be properly enclosed to prevent accidental contact with moving parts or energized coils. Additionally, installing protective covers or shields can further enhance the safety of the system. The enclosure and protection mechanisms should be designed to withstand the environmental conditions and anticipated forces during operation.

2.Regular Maintenance and Inspection:Regular maintenance and inspection of linear stepper motors are crucial to identify any potential issues that may compromise their safety. This includes checking for loose connections, damaged cables, worn-out components, and lubrication of moving parts. A well-maintained motor is less likely to malfunction or cause accidents.

3.Temperature Monitoring:Linear stepper motors can generate heat during operation, especially if they are subjected to continuous use or high loads. It is vital to monitor the motor’s temperature to prevent overheating, which can degrade performance and compromise safety. Temperature sensors and thermal management techniques such as cooling fans or heat sinks can be employed to maintain optimal operating conditions.

4.Overload and Overcurrent Protection:In industrial applications, linear stepper motors may encounter sudden load variations or excessive current flow. It is necessary to incorporate overload and overcurrent protection mechanisms to prevent damage to the motor or other connected components. These protective measures can include current limiters, fuses, or electronic control systems that monitor and regulate the motor’s current consumption.

5.Emergency Stop Functionality:An emergency stop (E-stop) button or switch should be incorporated into the linear stepper motor system to halt the operation immediately in case of an emergency or potential hazard. The E-stop function must be easily accessible and effectively cut off power to the motor, ensuring the safety of operators and preventing further damages.