1. Introduction

Currently, major therapeutic methods in the treatment of open, complicated and unstable fractures in traumatology, orthopaedics and surgery (limbs, joints, the pelvis, jaws, etc.) include external fixators. This therapeutic method provides the advantage of simple application of the external fixator with perfect stabilisation of the fracture,allowing for timely rehabilitation of the patient. External fixators can also be used to extend limbs or to correct axial deformities. However, no fixator has been made until now that would provide motor control of joint movement – advisable and desired for therapy associated with rehabilitation in unconscious patients or patients with complicated joint fractures. VSB-TU Ostrava has gained practical experience in this field in cooperation with University Hospital in Ostrava; fixator prototypes which are equipped with an electric stepper motor to control joint bending in patients exist.There are currently two solution variants that can be considered for the electric actuation, in principle.

1.1 Hybrid Actuators with Stepper Motors

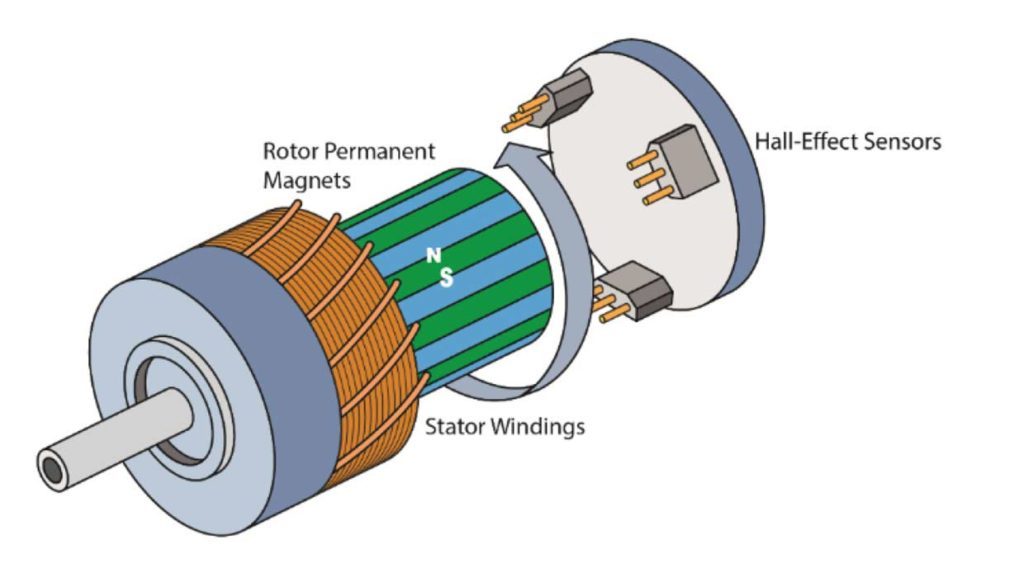

Hybrid linear actuator stepper motor transfer the rotation movement of the stepper to the movement of a linear screw with the help of a special patented nut. The actuator contains a hybrid stepper motor, which utilizes both the advantages of a reluctance motor and a motor with permanent magnets. The construction is based on a reluctance motor and ensures a small step angle (up to 0.9°) and fine resolution. The use of permanent magnets on the other hand increases the turning moment and provides a stronger motor. The composition of these two technologies together with the movement nut into a single case creates an affordable compact linear drive a hybrid stepper actuator.

Hybrid actuators represent an affordable solution for all application requiring small and exact control of a linear movement. Actuators create large forces in small spaces.The actuator contains a standard stepper motor, which may be simply controlled in the same way as stepper motors. The core of the hybrid actuator is an exact trapezoidal movement screw and nut shaped for the corresponding load. Integration of the movement screw in the motor provides a compact and precise drive unit which simplifies the construction of the resulting machine. Actuators find applications in medicine, measuring technology, handling technology and in other areas.

1.2 Stepper Motor Combined with a Linear Lead

The other possibility is offered by using a linear lead in connection with a standard two-phase stepper motor. The Kuroda linear lead used to convert rotational linearmovement can be mentioned as an example.The lead is equipped with a ball screw for positioning medium- up to heavy-weight

loads. The lead converts rotational movement of the stepper motor to the linear movement of the positioned load. An optimum configuration of the linear drive is obtained by combining the stepper motor and linear lead.

Which is Better for Cnc? Servo or Stepper Motors?

| Torque and Speed Considerations Of Stepper Motor |